Walsall Household Waste Recycling Centre & Waste Transfer Station

In a huge step forward for sustainable infrastructure in the West Midlands, our Morgan Sindall Construction team in the Midlands — working in partnership with Walsall Council and procured through Pagabo’s Major Works Framework — has delivered a £32 million Waste Transfer Station and Household Waste Recycling Centre.

Key Stats

- Difficult ground conditions due to known waterbed, requiring a series of ground remediation measures

- Use of innovative Sky Angel system to increase safety on site

- 46/45 Considerate Constructors Scheme score

- 354T carbon saved during construction

- £10.4k charitable/material donations throughout the project including £6.7k donated to Acorns Children Hospice in Walsall

- 386 apprenticeship weeks

At a Glance

Budget

£32.2m

Completion

July 2025

Location

Walsall

Framework

Pagabo

Sector

Industrial - Waste Depot / Recycling

Sustainability

99% Waste Diverted from Landfill

About the project

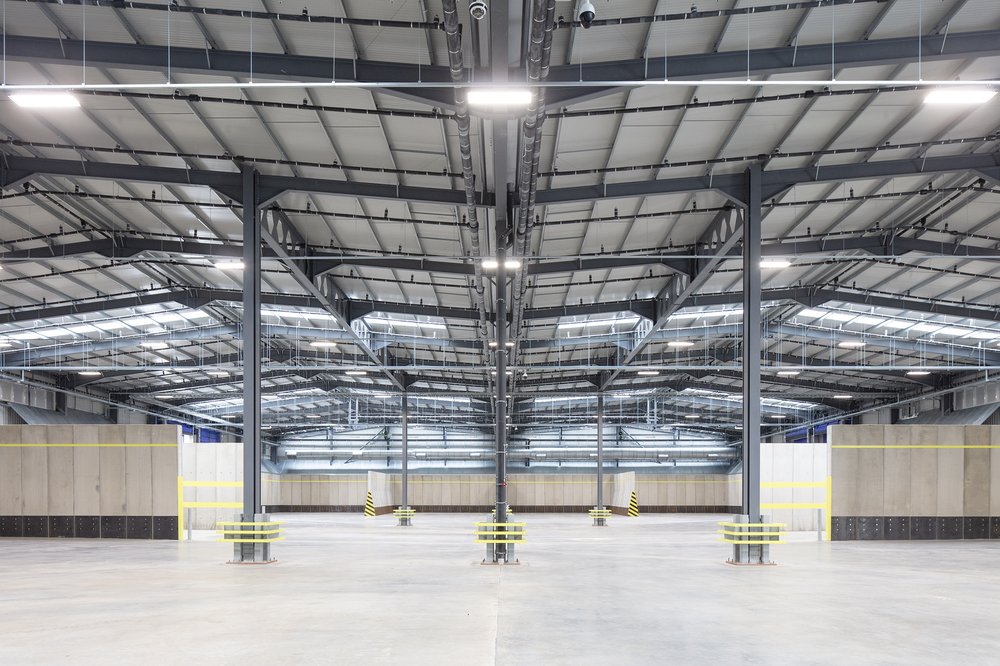

Located on a six-hectare brownfield site previously occupied by McKechnie Brass Ltd, the newly developed Waste Transfer System plays a pivotal role in Walsall Council’s long-term waste management strategy. The facility significantly strengthens the borough’s capacity to process waste, with the ability to handle up to 40,000 tonnes annually.

Key features of the facility include 19 dual-skip bays, a reuse shop with an integrated workshop to support circular economy initiatives, and a full suite of infrastructure such as weighbridges, odour control systems, fire suppression technology, and dust filtration units.

The site also houses modern office and welfare amenities to support both staff and visitors.

Strategic Foundation Redesign in Response to Adverse Ground Conditions

Initially, it was planned that the project would follow a traditional piled foundation design largely due to cost and programme efficiencies. However, as the team progressed with detailed site investigations, the reality of the terrain began to emerge.

The findings revealed extensive moisture retention across the site, with standing surface water and a central pond indicating poor natural drainage. In particular, low-lying areas exhibited saturated soils, raising very serious concerns about the long-term viability of a piled solution. In response to this, through a collaborative exercise including our supply chain, the team recommended a strategic shift to a pad foundation design. This alternative prioritised resilience and durability, aligning the foundation approach with the actual ground conditions rather than the original assumptions.

To enable this revised solution, the project team undertook a series of targeted ground remediation measures, which included:

- Site Clearance: Vegetation was removed, and the central pond was excavated to improve surface water management.

- Drainage Works: A ‘V’ trench was introduced to facilitate effective drainage and eliminate perched groundwater.

- Soil Management: Wet soils from low-lying zones were excavated and placed in windrows to accelerate drying through natural aeration.

- Ground Stabilisation: Once dried, the soil was treated with Ground Granulated Blast Furnace Slag (GGBS) cement, significantly enhancing its load-bearing capacity and suitability for pad foundation installation.

Sustainability and Environmental Performance

From the outset, sustainability was more than a goal — it was a guiding principle. The team along with supply chain and wider stakeholder support adopted a proactive approach to carbon reduction, notably through the “10 Tonne Challenge,” which aims to reduce construction-related carbon emissions by a minimum of 10 tonnes. This target was exceeded, with an additional 354 tonnes of carbon saved throughout the project. Key contributors to this achievement included the use of 60% Electric Arc Furnace (EAF) steel and the minimisation of concrete in structural elements such as the peninsulas.

Throughout the construction, energy efficiency was further enhanced via the deployment of GAIA Automate, an advanced energy management system that enabled an 80% reduction in on-site emissions.

Given the purpose of the project, the team made sure that waste management wasn’t just the end product, but a priority throughout the build. Overall, 98% of the construction waste was diverted from landfill.

Beneath the surface, the ground engineering works told their own story of innovation. Instead of importing new materials, the team re-engineered existing site soils using lime, recycled ground granulated blast-furnace slag (GGBS), and cement stabilisation — a sustainable approach that not only enhanced soil performance but also enabled effective surface water management.

And above it all, the roof of the new Waste Transfer Station was used to house solar photovoltaic panels to harness clean power and reduce the facility’s carbon footprint.

Driving Social Value Through Local Engagement and Community Impact

The project maintained a clear focus on supporting local employment and developing workforce skills. This was reflected in the fact that 69% of the workforce was recruited from within a 20-mile radius, contributing to the local economy and community engagement. In addition, the project provided practical industry experience to emerging professionals, with 19 apprentices and 5 graduate placements involved in its delivery.

Education and outreach formed a key part of the project's social value strategy. As part of this, the team facilitated nine school visits, aimed at engaging young people and raising awareness of career opportunities in construction and engineering. One notable initiative involved three local students who were invited to join Project Manager Steven Woodcock and Senior Business Development Manager Karina Connolly for a guided tour of the facility. This experience provided the students with insight into the project's role within the community and highlighted the importance of sustainable infrastructure.

Beyond workforce development, the project generated tangible social value through a range of community-focused initiatives. These included the donation of winter essentials to Walsall Outreach and the raising of £6,750 for Acorns Children’s Hospice through the recycling of scrap metal recovered from the site.

Read about our Project Spotlight Here

This project is a huge development for Walsall. What has been delivered here is truly a state-of-the-art facility, which will prove vital in ensuring we can continue to accommodate the waste demands we face in the Borough.

No project of this size comes without challenges but working with Morgan Sindall has been seamless throughout. It’s been fabulous watching the plans come into reality.”

Kathryn Moreton, Director of Place & Environment at Walsall Council

Gallery

Related News

NEWS

Morgan Sindall completes £11.7 million expansion and upgrade of Abbeywood Community School

Morgan Sindall Construction’s Cardiff and Bristol business has celebrated the successful handover of the new Olympus Building at Abbeywood Community School in Stoke Gifford, following the initial completion of …

NEWS

Final phase underway for Royal Parade improvement scheme

Morgan Sindall Construction’s South West business has begun the final phase of the Royal Parade Improvement Scheme in Plymouth, a major project set to enhance reliability along one of …

NEWS

Morgan Sindall Celebrates Key Milestone at Reading’s Central Library

Morgan Sindall Construction has completed the first phase of Reading's new Central Library, marking a significant milestone in the £10.7 million regeneration of the town's civic quarter.